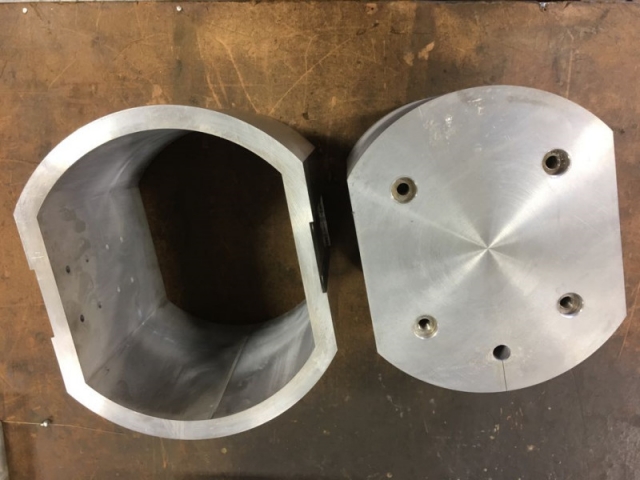

Wire Erosion Project – Outer Casing

Project Name: Outer Casing

Type of Work: Scientific Instrumentation

Client Requirements: Our client required a central aperture with tolerances on straightness of 0.015mm and a profile tolerance of +/- 0.02mm. In addition to this, the positional accuracy had to be within 0.02mm. The client also requested a quick turnaround.

The client also requested a quick turnaround.

Work Carried Out: At Cheshire Wire Erosion we always work closely with the client’s requirements. In this instance we wire eroded a central aperture. It is essential that accurate positioning and set up is in place in order to ensure metal is cut precisely and in the correct position.

Cheshire Wire Erosion carry out precision engineering using wire erosion. This is where, in this example the piece of metal is cut through with a strand of wire. The combination of the wire and the metal creates electrical sparks which are able to cut the material. This method of machining is accurate and is able to cut complex shapes even in hardened and tough materials and any surface finish can be achieved with fine holes easily drilled.

Due to our continual investment in the very latest and most up to date EDM technology along with our highly skilled workforce we are able to complete the most difficult and challenging tasks.

With this project we wire eroded a central aperture that adhered to the tolerances specified by the client and within the positional accuracy expected by them. We also completed this challenging project before the completion date. You can see the results from the photographs included.

Outcome: Our client was very satisfied with the result.

« A Sad Day for Cheshire Wire Erosion… | Wire Erosion Project – Keyway Wire Eroded into Long Sleeve »