Our services

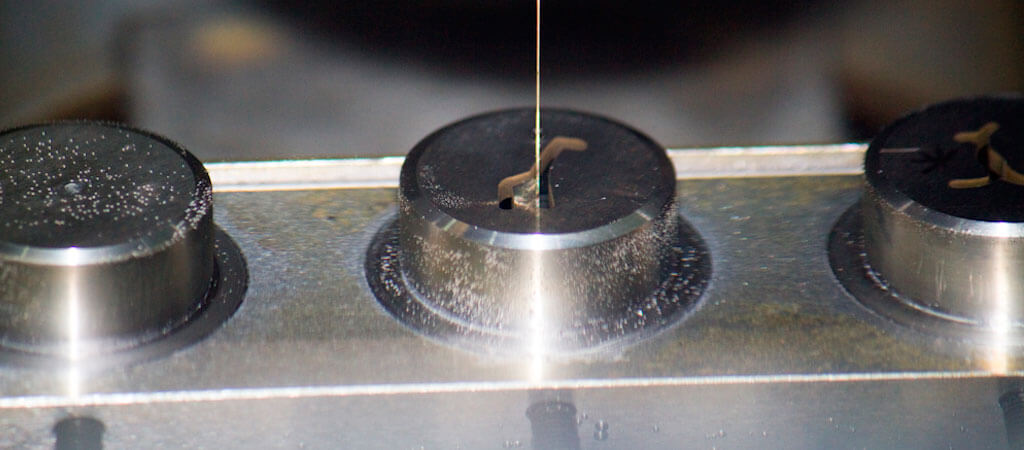

EDM (Electrical Discharge Machining) is all about precision engineering. It is a machining method that enables us to cut complex shapes or very small work pieces while maintaining close tolerances, even when working with tough or hardened materials. Conventional cutting tools cannot produce these, so when they reach their limit, EDM is the solution. It’s one of the reasons that EDM is used in a wide range of industries making it a valuable resource.

What is EDM?

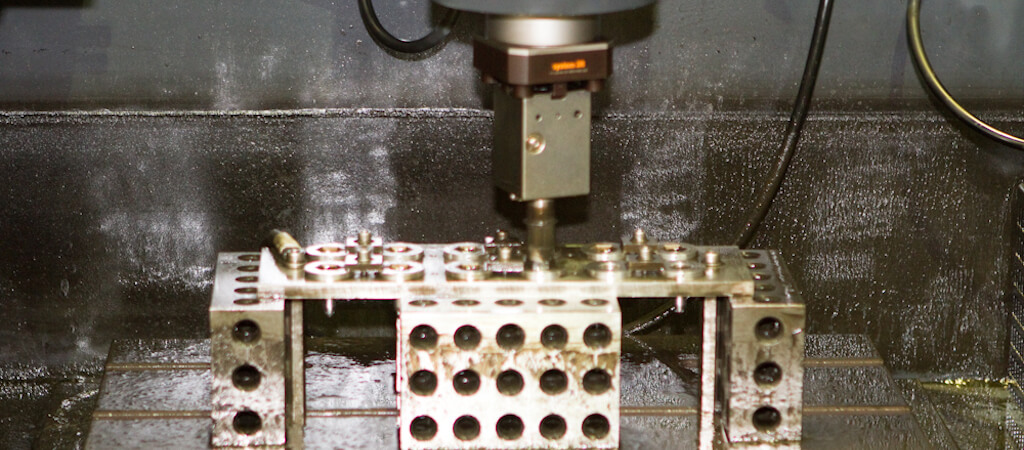

It involves removing material by discharge heat, by which its surface is melted and vaporised. Similar to laser cutting, it doesn’t need a mechanical force in the removal process, instead an electric discharge creates electrical sparks between the workpiece and the metal wire, as the wire moves along the material the sparks created remove the material.

Why use EDM?

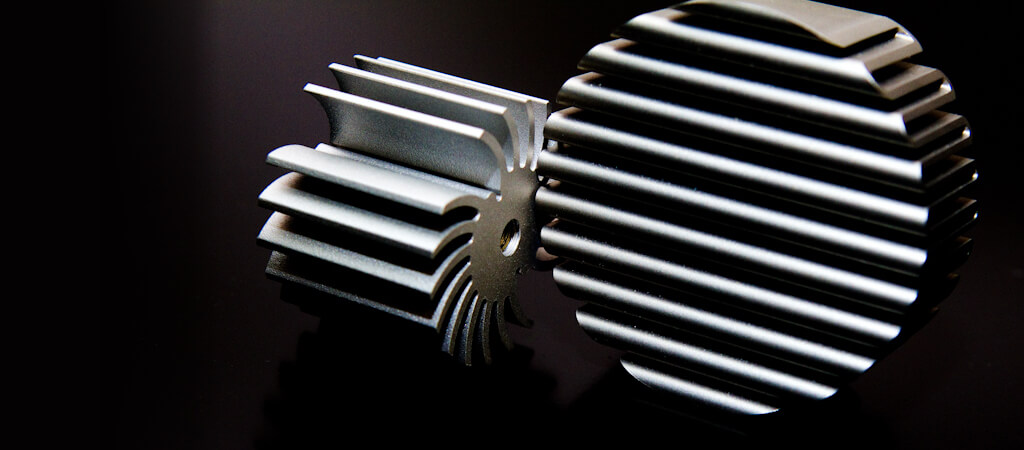

The advantage of EDM as a machining process is that it can provide high-definition accuracy for close and tight fitting parts. Repeatability is also an inherent characteristic of this machining method. EDM is also a great option when requiring delicate or fragile work pieces that ordinarily couldn’t take the stress and strain of traditional machining.

Wire-Cut EDM, Die-Sinker EDM and Small Hole Drilling EDM are cost-effective methods of cutting, shaping and re-sizing of hard or soft, electrically conductive materials. It’s also precise and time saving. What also makes EDM different to other machining methods is that it is a non-contact process that induces no stresses into the workplace.

Why Choose Cheshire Wire Erosion for EDM?

Cheshire Wire Erosion is an intelligent option for anyone looking for precision engineering.

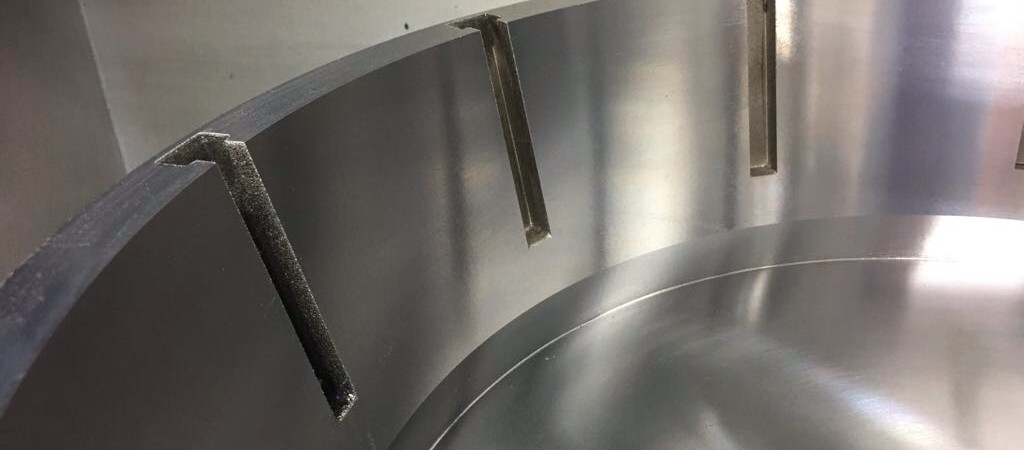

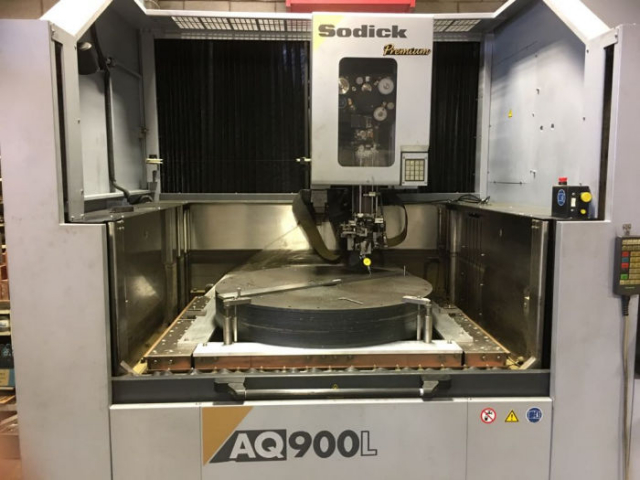

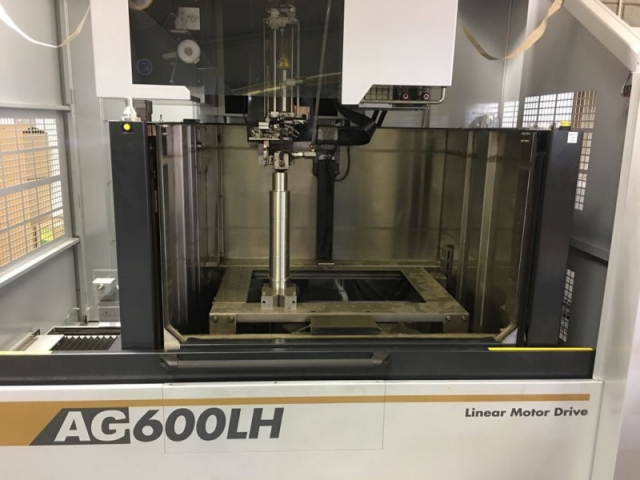

We offer a high-quality wire erosion service. With the range of technology we have, we can provide a variety of wire diameters which enable designs with differing corner radii to be cut. The machines can also ensure that the critical surface finish required is met and deliver components with tapered angles. These are just some of the features that we can produce with the technology that we have.

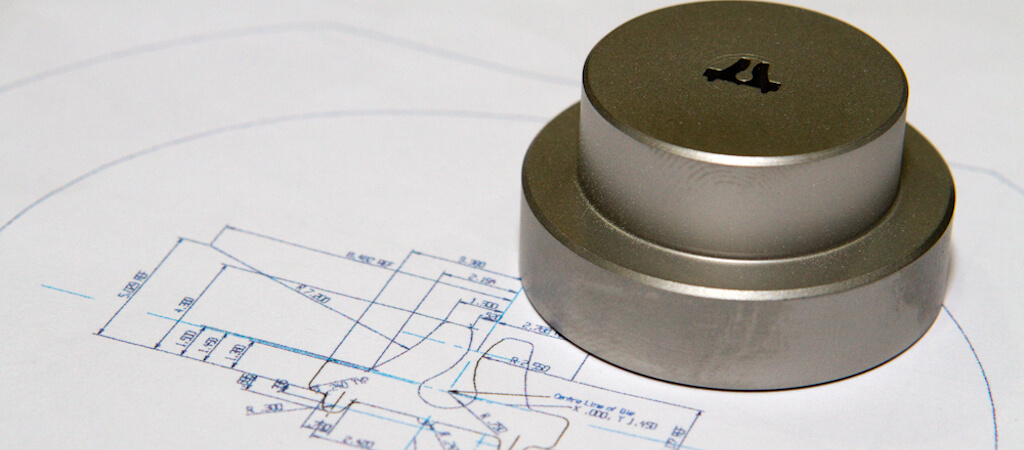

With bespoke engineering, we can accommodate your requirements no matter how exacting or specific these might be or what material is being used. We have the technology and expertise to manufacture components from non-exotic materials such as Copper, Steel, Aluminium, Brass or Tungsten Carbide or more exotic, less easy to conventionally machine materials, such as Titanium, Inconel, Nimonic Alloys, Graphite, Duplex, Silver and Gold etc. Over the years we have worked with most, if not all, of these materials.

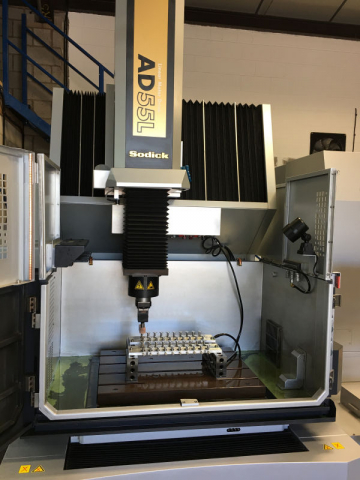

While we regularly invest in new technology and have a range of machinery produced by world leading company Sodick in our workshop, we also recognise the importance of investing in our staff. They are highly skilled and experienced engineers qualified in this type of machining, however, we ensure that they receive ongoing training and are kept up to date with new and innovative ways of using the equipment that we have.

Combining the use of the very latest EDM technology with experienced and skilled staff means you can expect a quality product, supplied on time and within deadline, all at a competitive price.

All our manufacturing processes are supported by our BS-EN-ISO 9001 accreditation.

Areas of Industry

- Aerospace

- Automotive

- Ceramics

- Electronics

- Food Production

- General Engineering

- Hobbyist

- Horology

- Jewellery

- Medical

- Motorsport

- Power Generation

- Petro Chemical

- Pharmaceutical

- Precision Engineers

- Railway/Locomotive Engineering

- Ship Building

- Universities and Colleges

Types of Work

- Precision Components

- Prototypes

- Small and Large Batch Work

- Exotic material Machining

- Extrusion Tooling

- Copper

- Aluminium

- Plastic etc.

- Press Tooling

- Mould tooling

- Plastic

- Rubber

- Selective Laser Melting Parts Removal