Wire Erosion Project – Keyway Wire Eroded into Long Sleeve

Project Name: Keyway Wire Eroded into Long Sleeve

Type of Work: Process Machinery Part

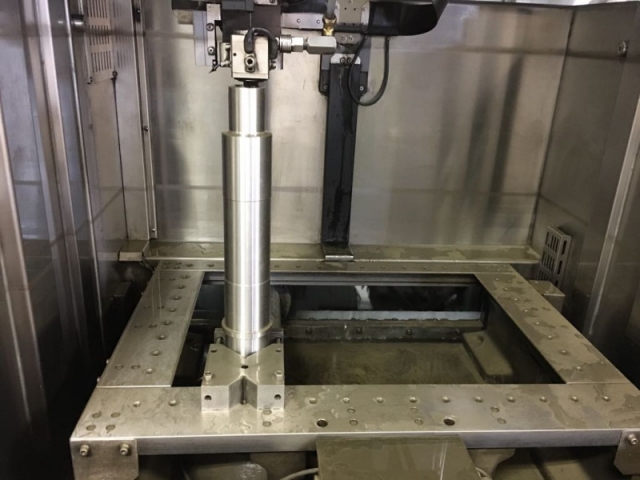

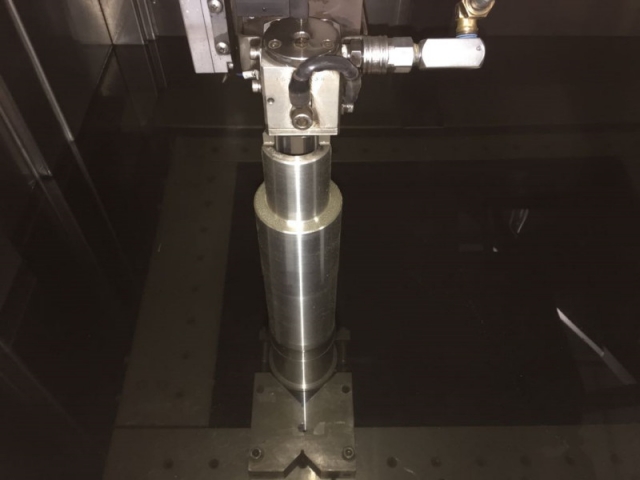

Client Requirements: When the client approached us with this piece of work, they had already contacted several other subcontractors who were unable to complete the task because they did not have the right resources due to the large size required. As a result, the client asked Cheshire Wire Erosion if we could wire erode a keyway through a full sleeve length of 465mm.

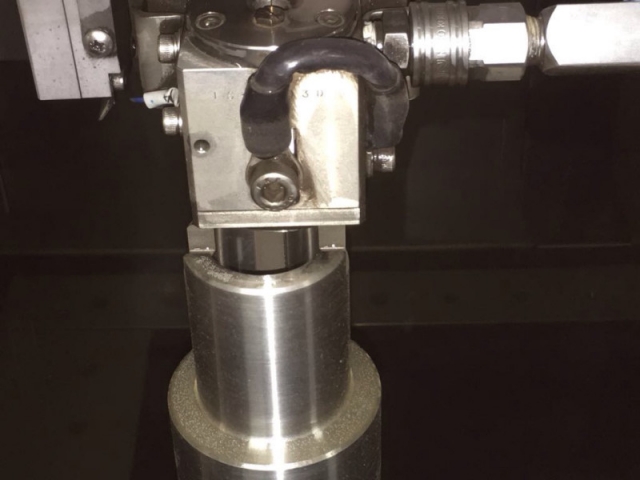

Our client had very detailed specifications that we were required to adhere to. We were asked to erode the keyway to a tolerance of +/- 0.015mm with a positional accuracy within 0.010mm. The keyway size was 14.35mm wide and 6.35mm deep. Obviously with this type of precision engineering there was no room for mistakes!

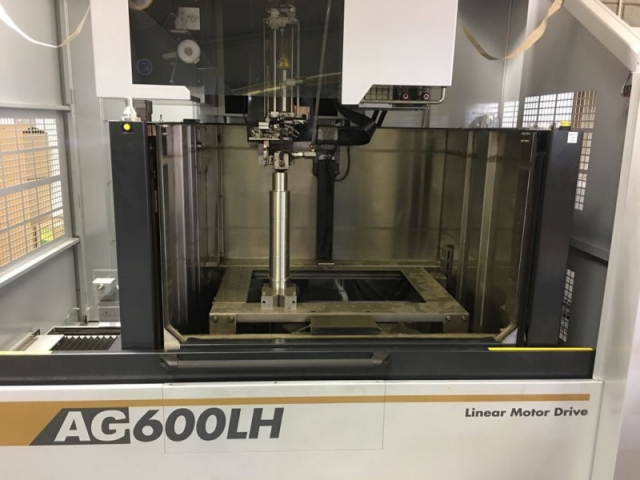

Work Carried Out: Using our recently acquired Sodick AG600 LH machine we were able to wire erode the keyway to the exact specifications given to us by our client. This included wire eroding to the tolerances required on three of the sleeves.

One of the main advantages of having the Sodick AG600 LH machine is that it has a workpiece thickness of up to 500mm. For this project, using this machine enabled us to work accurately and with precision to cut the more complex sizes and shapes that were required, so we could meet the client’s specifications.

Such is the ease at which we can complete complex tasks like this one, using our state of the art EDM machines, means we were able to finish this project in 2 days.

With our ongoing investment into new EDM machines, we like to keep up to date with developments in manufacturing and ensure we have the very latest technology in our workshop. This ensures we always have the resources to complete tasks that other companies are unable to.

Outcome: Our client was really pleased with the speed at which we completed the work and the results.

« Wire Erosion Project – Outer Casing | Separator Plates – Wire Erosion of Multi Plates »