Spark Erosion Project – Drain Hole into Super Duplex Pump

Project Name: Spark Erosion of Drain Hole into Super Duplex Pump

Type of Work: Housing /Chemical

Client Requirements:

Inconel is a super alloy and is known for being oxidation-corrosion resistant. This makes it highly suited to withstanding extreme environments when subjected to pressure. As a tough material this also makes it difficult to machine using conventional machinery. That’s when having the very latest wire erosion technology is essential.

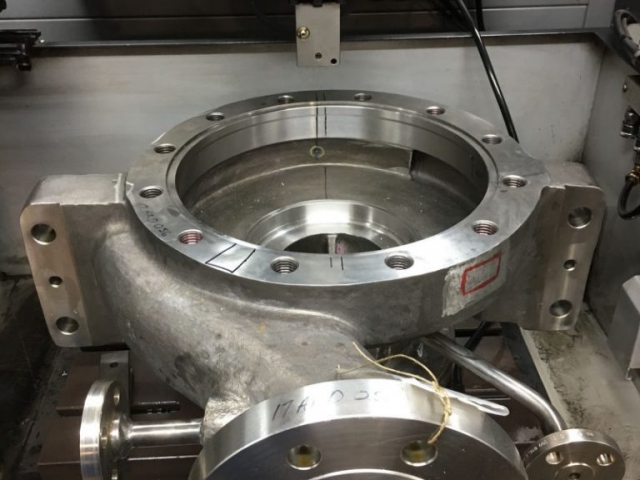

Cheshire Wire Erosion was recently asked to spark erode a lateral “drain hole” into an Inconel pump impellor housing. While this was a complicated process it was made even more complicated because of the angle required and the position of the hole. Out client also needed a quick turnaround time because of production down time.

To complete this project, we used our Sodick AD35L which allows for optimum performance at high speed and rapid acceleration. The linear motor drive system has no mechanical contact resulting in stable machining accuracy and reliability.

Work Carried Out:

The drain hole, it was too large to be spark eroded using the Sodick AD35L in a normal submerged condition. Because of its size we had to rethink our approach to the project. We decided to machine the metal with the door of the Sodick AD35L open. We also created a reservoir of water by using a metal plate and modelling putty. You can see what this looked like from one of the photographs included. Once this was in place, we carried out the process of spark erosion to create the drain hole.

Using spark erosion was the perfect type of machining to use in this instance as it enabled us to easily and effectively machine a hardened and difficult to machine material. This type of work is not undertaken very often because of its unsafe characteristics. Because of the skills and experience of our engineers, coupled with the technology we have in our workshop, we were happy to carry out the project based on the customers necessities. We were confident we could meet their requirements and we did! The project was completed on time and with a very happy customer!

While we have at our disposal the very latest technology, at times, due to the complexity of a project we have to draw on our experience and adapt the machinery that we have to accommodate these requirements. Problem solving is an integral part of what we do at Cheshire Wire Erosion. We are constantly working to find solutions for our clients. We improve and adapt to produce precision parts. This is all part of the professional service that we offer at Cheshire Wire Erosion, we tailor our services to meet your needs.

If you would like to find out more about spark erosion and wire erosion, give Cheshire Wire Erosion a ring on 01270 753323

« Wire Erosion of 4-Axis profile – Paper Shredder | Precision Wire Cutting – Pastry Cutters »