Cheshire Wire Erosion invest in New Sodick AD55L Sinker EDM

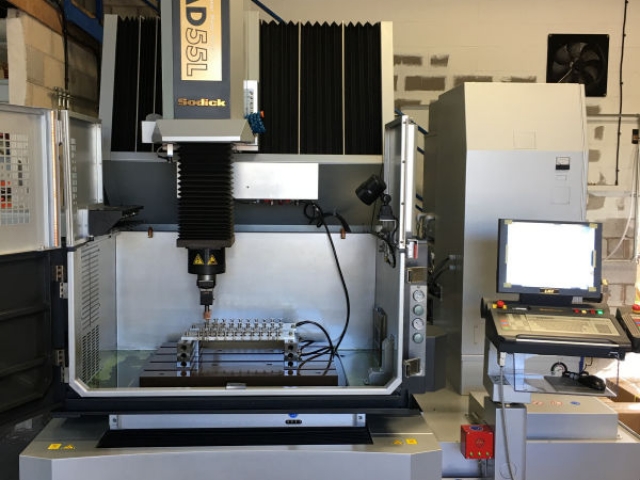

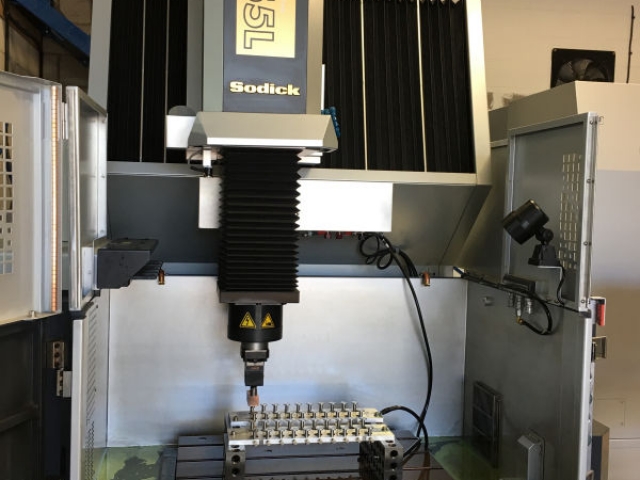

Cheshire Wire Erosion recently took possession of a brand new AD55L from the Sodick range of die sinking EDM. We are keen to keep up with developments in EDM and invest in new technology to ensure we are able to give our customers the very best service and produce superior results.

The Sodick AD55L machine comes with all the latest technologies such as linear motors, ceramics, motion controller and discharge units. The advancements made with this machine mean that the AD55L can provide higher manufacturing efficiency and shortened delivery time.

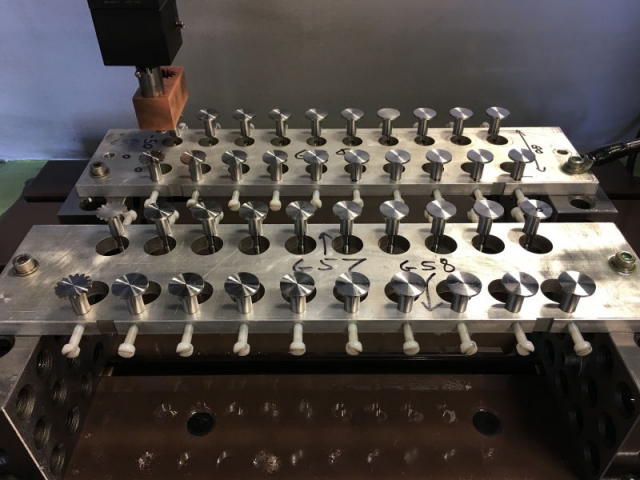

The AD55L, with its larger table, can accept larger work pieces or accommodate multiple set-ups, using the integrated Multi-Tool Changer. It has a work tank that will accept workpieces of 1200mm x 800mm x 400mm with XYZ travels of 600mm x 400mm x 400 mm and a maximum workpiece weight of up to 1,000 kg.

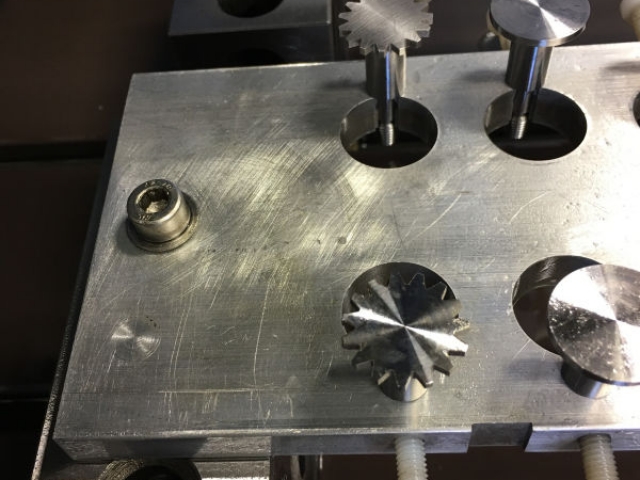

This machine can provide a good sliding fit and excellent surface finish. It can cut to the most microscopic detail by using electrical discharges. These rapidly recurring current discharges are between two electrodes, separated by a dielectric liquid and subject to an electric voltage. The current melts the material and with this machine can cut between 50 – 60 microns. The dielectric cooling unit means that materials can solidify in the cooler at 1,000 times a minute.

The machine can also be set up to run all night and out of normal working hours if necessary. For our customers this means we can produce large numbers of pieces within a tighter deadline. It also has larger work pieces and multi set ups due to its tool changer.

« Wire Erosion – Impeller Splining | Challenging Times Require Consistency and Reliability! »