Wire Erosion Project – Power Press Drive Shaft Repair

Date: July 2016

Type of Work: Repair

Client Requirements:

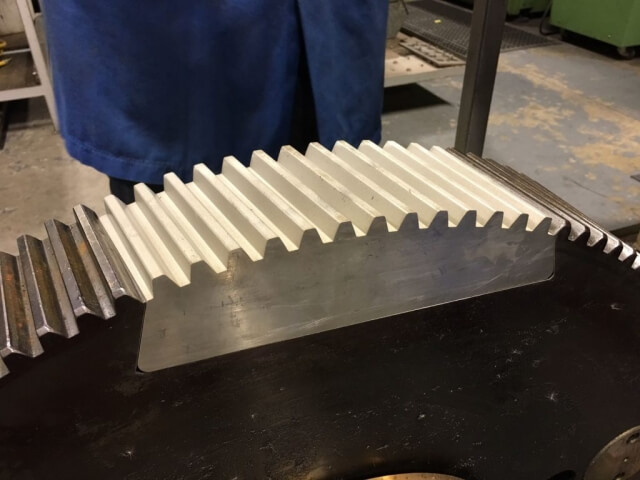

We were asked to fix the Helical gears at both ends of a power press drive shaft which were damaged. Due to the damage incurred the damaged portion of the gears needed to be removed and then replaced with steel inserts. For this to work the new steel inserts had to be a good fit and there was no room for mistakes to be made in this situation. The intricate nature of this task required attention to detail, also ensuring that the necessary timing between all teeth was maintained.

Work Carried Out:

Because of the characteristics of the Helical gears replacing them is not straight forward. The first step to fixing the problem was the sub can removal of the damaged teeth portion. The next step was to take accurate measurements of the portion removed and we used our new Faro Arm to do this. The Faro Arm is one of the world’s most innovative portable measurement solutions and bestselling measurement arm. At Cheshire Wire Erosion we pride ourselves on keeping up to date with developments in the world of engineering and because of this we recognise the importance of acquiring and using the very best, and most up to date technology and we strive to do this on an ongoing basis.

The Faro Arm is a piece of technology that enables us to carry out accurate dimensional analysis and it proved invaluable in this instance because with the accurate measurements we had obtained from using this technology, templates for the front and rear faces were wire eroded. These were created so that the correct size, fit and timing with adjacent remaining teeth, was maintained. The process was repeated for both gears at opposite ends of the shaft.

Due to the material costs and wire erosion cutting rates, aluminium inserts were firstly wire eroded to all the sizes, and fits etc that we had achieved earlier. These aluminium blocks in conjunction with timing gauges that sat on top of the old and new teeth confirmed a perfect job! This meant that we could then cut the finished inserts from steel, once again checked with the timing gauges and Faro Arm, knowing that they would be accurate and a perfect fit – see photos.

The result…the customer was “over the moon”

« Wire Erosion Project – Aerospace | Wire Erosion Project – EDM Drilling with a Sodick K1C »