Wire Erosion – Drive mechanism

Project Name: Wire Erosion – Drive mechanism

Type of Project: To create a scientific component made from Aluminum

The Industry: Petro Chemical

Client Requirements:

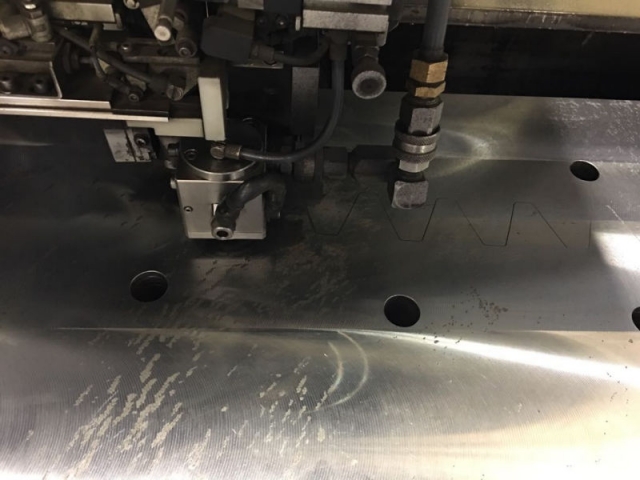

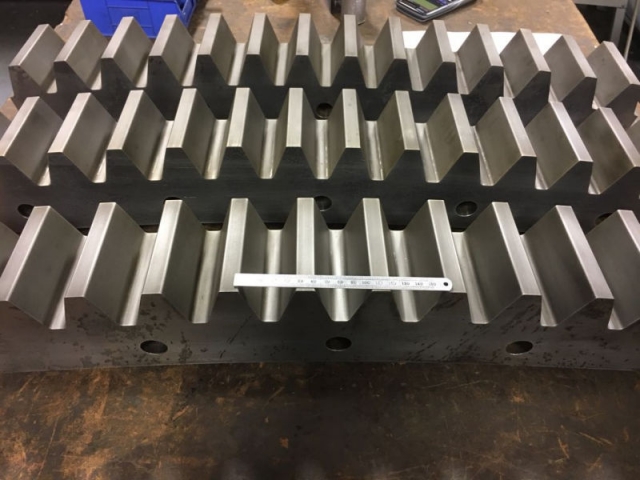

We used a 110mm thick steel plate from which we cut the 20 sectors. There were five pieces, and we wire eroded each piece in order to create 5off dowel holes and outer profiles x 20. With our wide range of wire erosion machinery, used to perform a broad spectrum of applications, we can produce pieces that are cut to our clients exacting standards and specifications. With this project we used our AQ900L Sodick wire machine.

With the AQ900L Sodick wire machine we were able to cut the aluminium according to our client’s requirements. However, in addition to Aluminium, this piece of machinery has the ability to cut a wide variety of other materials including carbide, exotic steel alloys, titanium and tungsten. This piece of technology means we can wire erode the most difficult to cut machine conductive materials efficiently and accurately and with precision. The parts that the machine can produce can be from 1mm up to 450mm in thickness and from a few grams in weight to up to 400kg in weight.

If you want to see what this involved and what the end product was like, take a look at the photographs included.

At Cheshire Wire Erosion we pride ourselves on the repeat business we receive and from recommendations. This is because we have a reputation for producing quality components. In this instance we were contacted by the company as a result of being recommended by a client we have previously done work for. Whether big or small we can accommodate your requirements. We have experience of working with multi-national companies in various industries such as aerospace, automotive and as with this project the petro-chemical industry.

Over the years we have also developed a proven track record for speed of manufacturing and delivery of service. We recognise the importance of investing in our staff and so provide ongoing training. As a result, have a group of highly skilled, experienced employees. Paired with this we continuously invest in the very latest wire erosion and spark erosion machinery.

For your peace of mind, we have all the necessary accreditations assuring you that any work carried out will be completed to the highest industry standards in quality and delivery.

For more information about wire erosion ring Cheshire Wire Erosion on 01270 753323.

« Cornish Birds of Prey Centre and Animal Park | Spark Erosion – 4-Axis Aluminum Component »