Spark Erosion – 4-Axis Aluminum Component

Project Name: Spark Erosion – 4-Axis Aluminum Component

Type of Project: To create a scientific component made from Aluminum

Client Requirements:

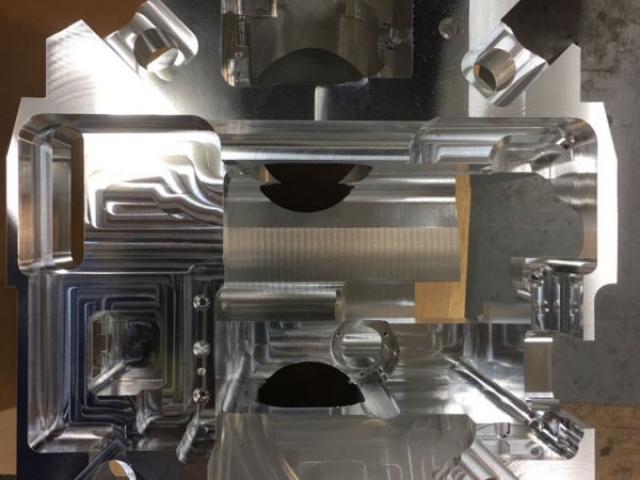

Cheshire Wire Erosion is able to create new components based on the requirements of our clients, however at times we are sometimes asked to alter existing components. This may involve a slight adjustment, or several operations carried out on it. An example of this is a recent project we undertook for a client who had a complex 4 axis conventionally machined aluminium component.

The component that they sent us required several “deep” machining operations as well as the removal of radial corners. Using conventional technology would not produce cutter lengths of 200mm+ as they were too deep, instead specialist machines were needed to carry out the required machining operations.

Work Carried Out:

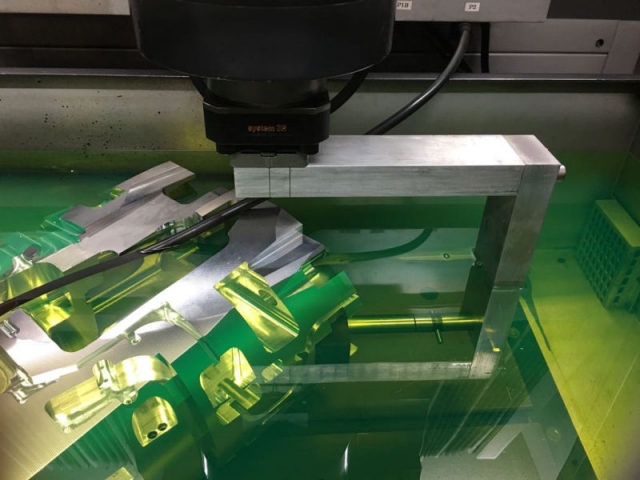

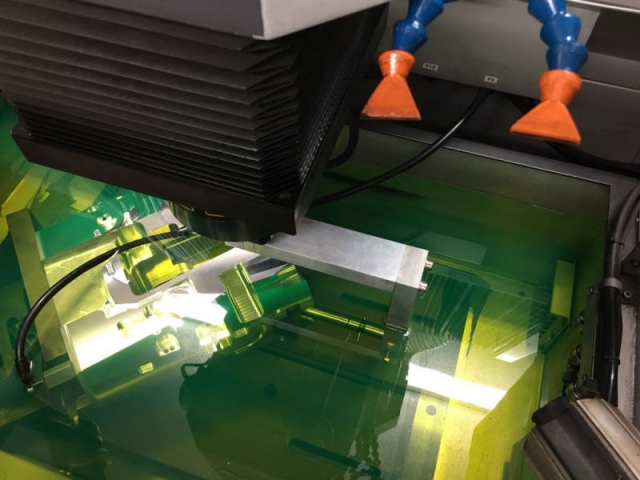

For this project the client had very detailed specifications regarding the sharp corners and pocket depths required. To carry out this type of work, conventional machining would not have been sufficient. As a result, we used our AD35L Sodick Spark Eroder to perform solid sink spark erosion.

You can see the process followed with this project and the various stages of it from the photographs included as well as a video demonstrating our use of the AD35L Sodick Spark Eroder. This piece of technology can accurately and effectively spark erode an Aluminium component as well as other materials such as Carbide, Inconel, Titanium and Bronze. We were able to complete the work on the aluminium component to the customers specifications. We were also able to provide the client with a quick turnaround time.

We have worked with this client for over 20 years and to quote what they said about this project, “they know what they are doing.” We tend to agree with them, we do know what we are doing! It’s our combination of skills and expertise combined with our continual investment in the very latest technology that makes Cheshire Wire Erosion the company to use when you have a component you need producing, or an existing component that needs altering.

Over the years we have developed our knowledge and understanding of spark and wire erosion meaning you can expect a professional service every time, along with a quality component machined or modified to your specifications, no matter how exacting. Cheshire Wire Erosion has established itself as providing reliable, precision, engineering and we are proud to have many clients who continually use us to carry out work for them. Regardless of how difficult or complex the project seems to be, they know we can get the job done!

For more information about spark erosion ring Cheshire Wire Erosion on 01270 753323.

« Wire Erosion – Drive mechanism | Wire Erosion – Split Bearings »