Wire Erosion Project – Aerospace

Date: November 2016

Industry Sector: Aerospace

Type of Work: Wire Erosion

Client Requirements:

Over the years we have worked with many successful companies within the aerospace industry and an example of this was when we were asked by one of our aerospace customers to wire erode several components that were to be used in aero engine blade manufacture. This included 2 x 2 Wire erode inserts, 2 operations roughing cut and 2 operations finishing cut. While this might seem straight forward, it was made challenging by the fact that the material we needed to cut was a steel alloy which meant it was very expensive and very tough to machine conventionally.

Work Carried Out:

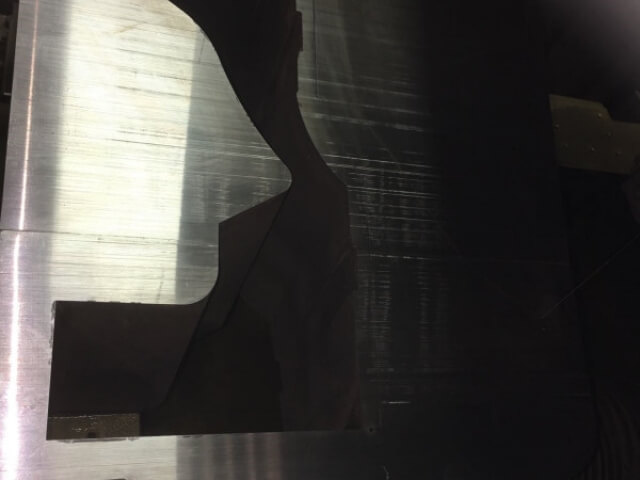

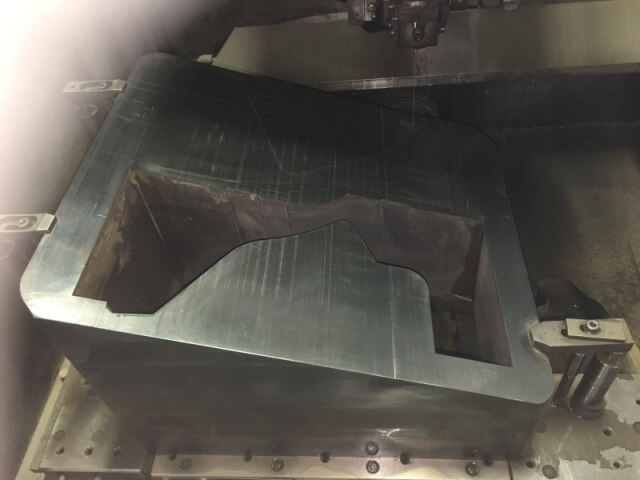

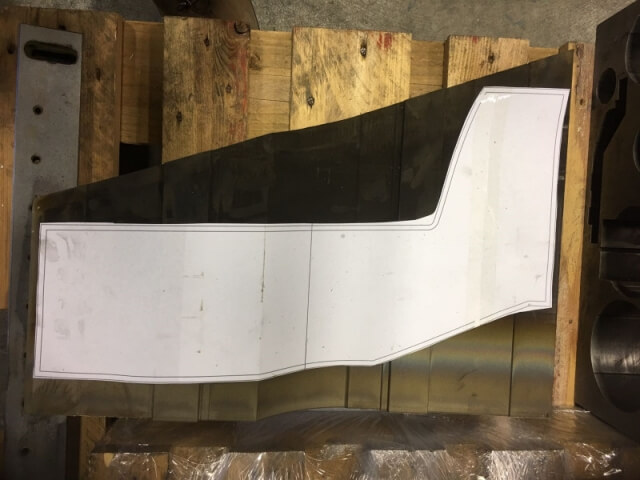

Because the steel alloy was so expensive there was no room for error when cutting the metal as this could prove to be very costly, so utilisation was critical. We received the blanks from our customer in the form of a large cheese wedge (see photos) with a large angled top face.

We began the process by firstly drilling a stat hole and then we set up blocks. For this specific project the component requirements involved multiple operations. An initial set of cuts leaving a 4mm allowance was made. Due to the nature of the material, the amount of material that had to be removed, and the complexity of the profiles, stress relieving was carried out. Following this, and on the basis of the drawing sizes, secondary finishing cuts were made. Using our EDM die sinking machine, further operations were then undertaken in order to produce other complex and difficult to machine details. Due to the complexity of the profile, very little conventional machining took place on the finished parts.

« Wire Erosion Project – Restoration | Wire Erosion Project – Power Press Drive Shaft Repair »